Yogurt Production Process

Description

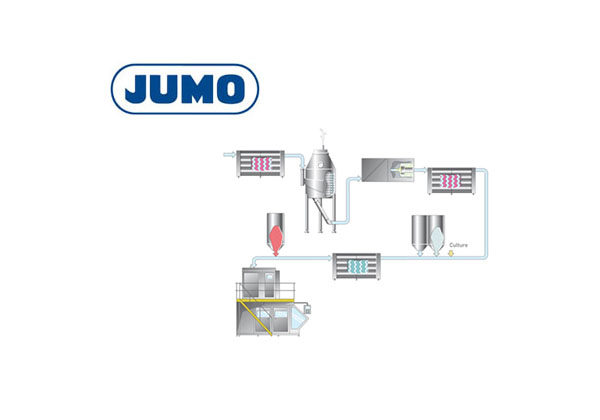

Yogurt production is used to typify the production of all fermented products. The milk to be used is pre-treated according to the product to be manufactured, and undergoes a standardization process to ensure a specific fat content. It does not matter whether you are making set yohurt, stirred yogurt, drinking yogurt or another fermented product such as sour cream, crème fraîche, kefir, buttermilk or sour milk, the core process is the same. The milk is brought to the required fat content for the desired end product. After homogenization and pasteurization, the bacterial culture specific to the particular product is added to the milk and incubated. Once products reach the optimum pH value, they are cooled, a fruit mixture is added if required, and then filling takes place. This is usually under aseptic conditions, in order to avoid recontamination.

Yogurt process technology is described below on the basis of individual sub-processes. Click on the process to display the related JUMO product portfolio and get specific details about measurement and control systems you need.